Bring-Up

What is Hardware Bring-Up?

Once manufacturing of the PCBAs has been completed, they need to be tested to verify they work as intended. Bring-up is the process of verifying the product functions as expected in a nominal environment. Depending upon the state of the product development (initial prototype vs volume production), the approach for Bring-up may vary. For the initial prototypes, the lead engineer typically works with team members in a hands-on approach. As the design transitions to volume production, automated test procedures are created to minimize test time while ensuring sufficient test coverage.

More extensive testing is reviewed in the Product Test phase.

Arira’s role in Hardware Bring-Up

During the Prototyping Phase for the initial prototypes, Arira will generate a test plan with detailed procedures for verifying the functionality of the product. The first part of the test plan will cover basic hardware functionality, and will be executed by an Arira team member. Once the basic hardware functionality has been verified, extended team members are brought in to help fully test the product.

As the product transitions to volume production, Arira will work with the CM and the automated test development team, if applicable, to generate a plan for automated test of the product. The test plan will emphasize fully testing the product in an efficient manner to minimize test time, and, ultimately the costs associated with the testing.

Bring-up Test Plan

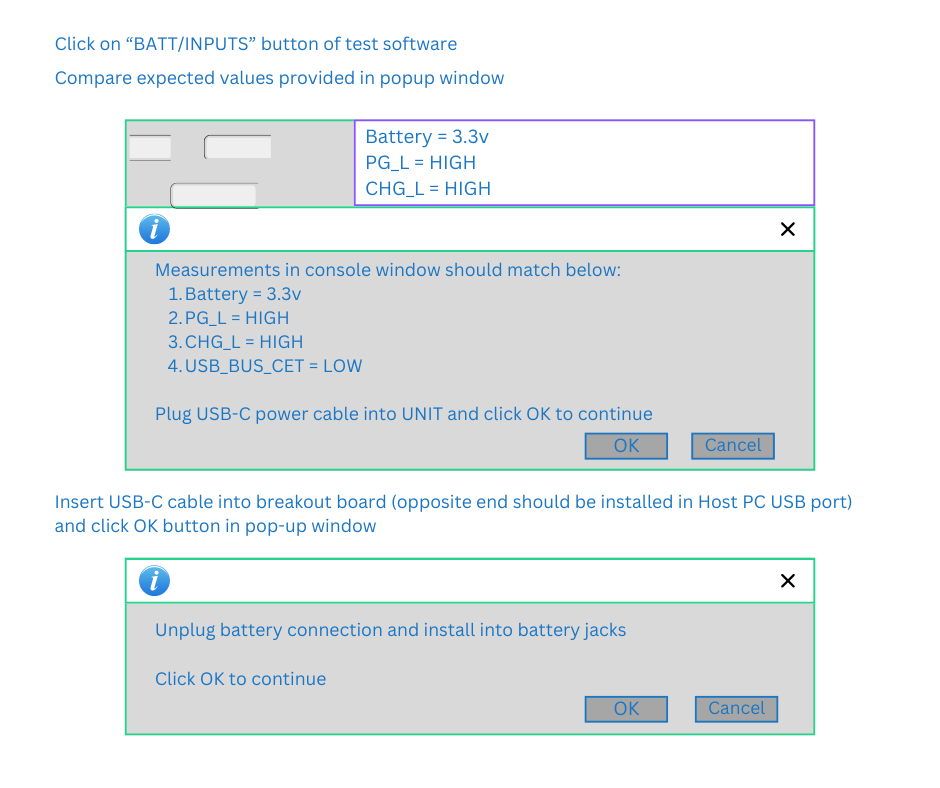

The Bring-up Test Plan contains a list of equipment required and the steps required to test the to test the product. Typically, a Bring-up Test Plan requires a human to execute. When measurements are required, the Bring-up Test Plan also functions as a means of recording and reporting the results of the measurements.

PCBA Status

Typically, multiple PCBAs are Manufactured, and, frequently, they end up in different locations. In order to track the status of each, a log is generated that indicates where the PCBA is physically located, what level of testing has been completed, and what, if any, rework has been completed on the PCBA. Usually, the serial number of the PCBA is referenced in the log as it is a unique indicator.As-needed rework

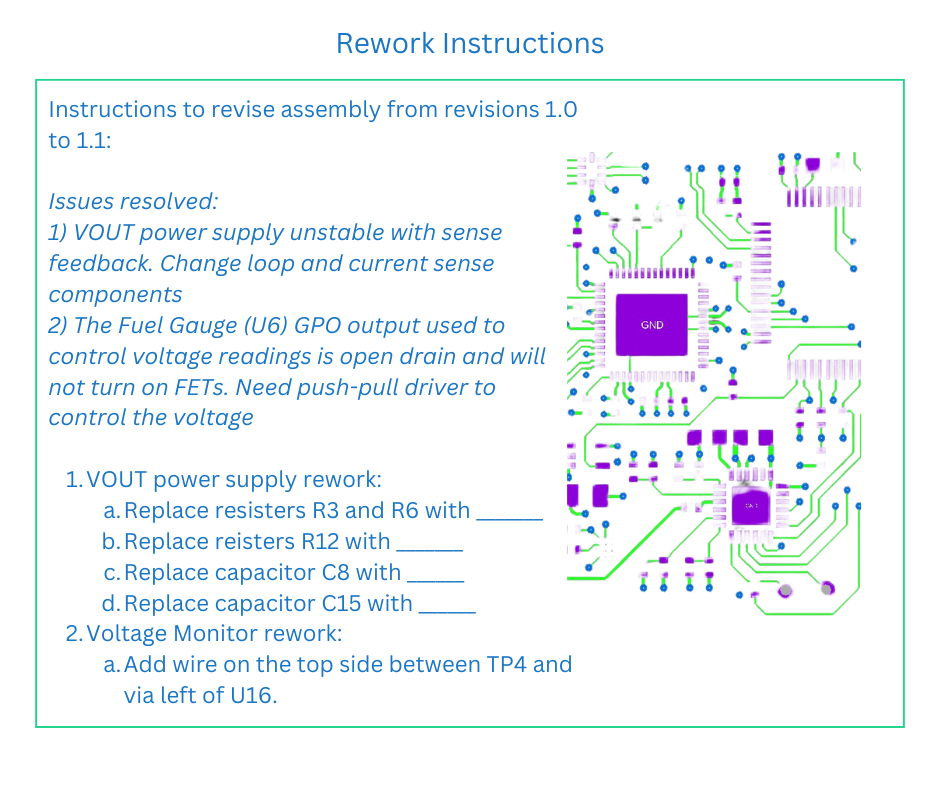

If a change to the hardware is required, the change is documented in a set of rework instructions. Rework instructions are tracked by a unique revision level. Each revision level features a brief description of the change along with detailed instructions outlining the required modifications.

Praise from Our Partners

Michael Johnson, Head of Products

Performance Software

"Arira has provided excellent engineering services for the development of hardware for an avionics product. Their highly skilled and experienced engineering resources have been invaluable in the overall support of high quality and efficient product development. Arira has proven to be very adaptable to the complex and changing requirements as well as providing invaluable support in working with other development partners. Arira delivers a great customer experience."

Justin Dollinger, Engineer

Room Inc.

"Arira Design is truly a one stop shop for everything electronic. The team has helped us with everything from circuit board design to firmware development to safety certifications of high voltage systems. The team is always quick to respond, treats us fairly, and operates gracefully when we tend to increase the scope mid-project. Overall, I would strongly recommend Arira Design to anyone looking for similar help."

Kenneth North, VP of Engineering

Elo Touch

"Elo has been using Arira Design for their schematic and layout review, as well as PCBA design services for the past 20 years. Arira offers a quick turnaround and detailed design review process. They've been able to find issues that even our internal resources have missed. Saving Elo weeks, if not months, of potential schedule impact by making these changes later. Arira's engineering review team, on numerous occasions, will get on a call to explain their findings so the same mistakes don't occur ... We would recommend Arira's services to anyone looking for schematic/layout review or design services."

Jim Reding, CEO

Aroma Retail

“Positive: Professionalism, Quality, Responsiveness, Value

Excellent R&D partner. We developed a control module with mobile app from scratch, for a new aroma diffusion machine with a completely unique user interface. The entire Arira team was highly knowledgeable, reliable, transparent, and professional. While the project was completed under budget and on time, and the final product far exceeded my expectations, the most important value to me was the relationship. Arira Design, with Craig Paulsen as my main point of contact, remains an important ally as they help me navigate the current global supply disruptions. I cannot over-express my gratitude for their concern and help in making sure I do not run out after launch of the new machine. It was Craig from Arira that reached out to me to alert me to the long-lead issues that required early purchase or substitutes; otherwise, I would not have seen it coming soon enough to adjust. I consider Craig and his crew an extension of my team.”

Client in stealth mode

"Arira just handles it. I can't say that enough. I can throw things over the fence, not look into every detail and they work with me to define our product. I don't feel overburdened with every single detail up front, and they're very quick to react and make changes. We've been able to keep designs flexible and serviceable. For a growing company looking to find our product market fit I can't imagine a better experience. Craig is a pleasure to work with, is incredibly knowledgeable and handles my stupid questions very well. The supporting engineers he's brought directly to us like James or behind the scenes have always been very professional and knowledgeable."